US firm honored for role in first-ever controlled fusion ignition

What's the story

General Atomics, a US-based company, has been honored with the R&D Team of the Year award at the esteemed R&D 100 Awards. This recognition is often compared to a "Nobel Prize" for engineers and innovators. The accolade was bestowed in acknowledgment of their revolutionary 4Pi system, which played an instrumental role in achieving the world's first successful controlled fusion ignition.

Technological triumph

4Pi system: A key player in fusion ignition

The National Ignition Facility (NIF) at the Lawrence Livermore National Laboratory in the US, utilized General Atomics' 4Pi system to achieve this groundbreaking feat. This marked a historic moment when scientists were able to generate more energy from fusion than what was used to initiate the fusion reaction. The success of this experiment demonstrated that it is possible to produce clean energy from nuclear fusion on Earth.

Energy process

Understanding nuclear fusion

Nuclear fusion is a process where two small atomic nuclei fuse together to form a larger nucleus, releasing enormous amounts of energy and heat. This process powers the stars, including our Sun, where hydrogen atoms combine to form helium. Since the 1950s, scientists have been trying to harness this process on Earth as a source of abundant clean energy.

Experiment details

A closer look at the first successful ignition

In 2022, during the first successful nuclear fusion ignition experiment, the NIF team used an inertial confinement fusion (ICF) method. They placed a tiny pellet filled with deuterium and tritium fuel in a capsule, and used 192 powerful lasers to fire at it from all directions. The lasers generated intense heat and pressure, compressing the fuel to extreme conditions needed for nuclear fusion. The energy released from this reaction exceeded the energy input, marking a successful ignition.

System significance

The role of 4Pi system in fusion ignition

The 4Pi system developed by General Atomics played a critical role in this experiment. It served as a diagnostic tool measuring conditions within the fusion capsule which is typically only 2mm in diameter, and needs to be free from any defects for successful ignition. The 4Pi system helped scientists maintain the quality of the fusion capsule by automatically screening it, detecting defects, and making precise improvements during the fabrication process.

System features

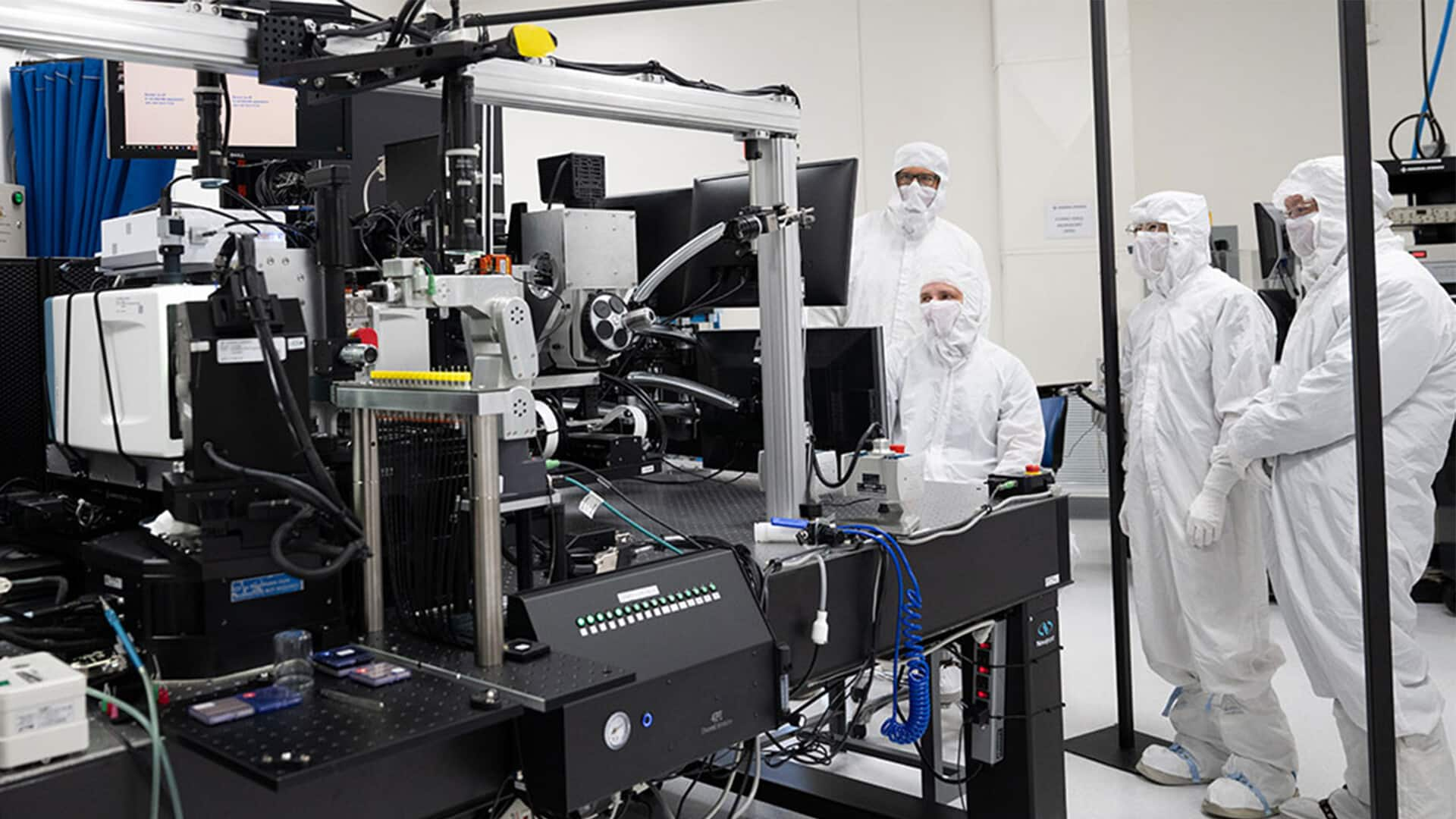

A blend of robotics and machine learning

The 4Pi system integrates up to eight instruments within a unified coordinate system, which includes robotics, automation, batch evaluation, as well as machine learning (ML) technologies. This approach eliminates measurement flaws that can arise from manually transferring a target between instruments, and enables the identification of the highest-quality targets from each production batch. Since December 2022, scientists have conducted successful fusion ignition five times, with the 4Pi system being an integral part of these experiments.