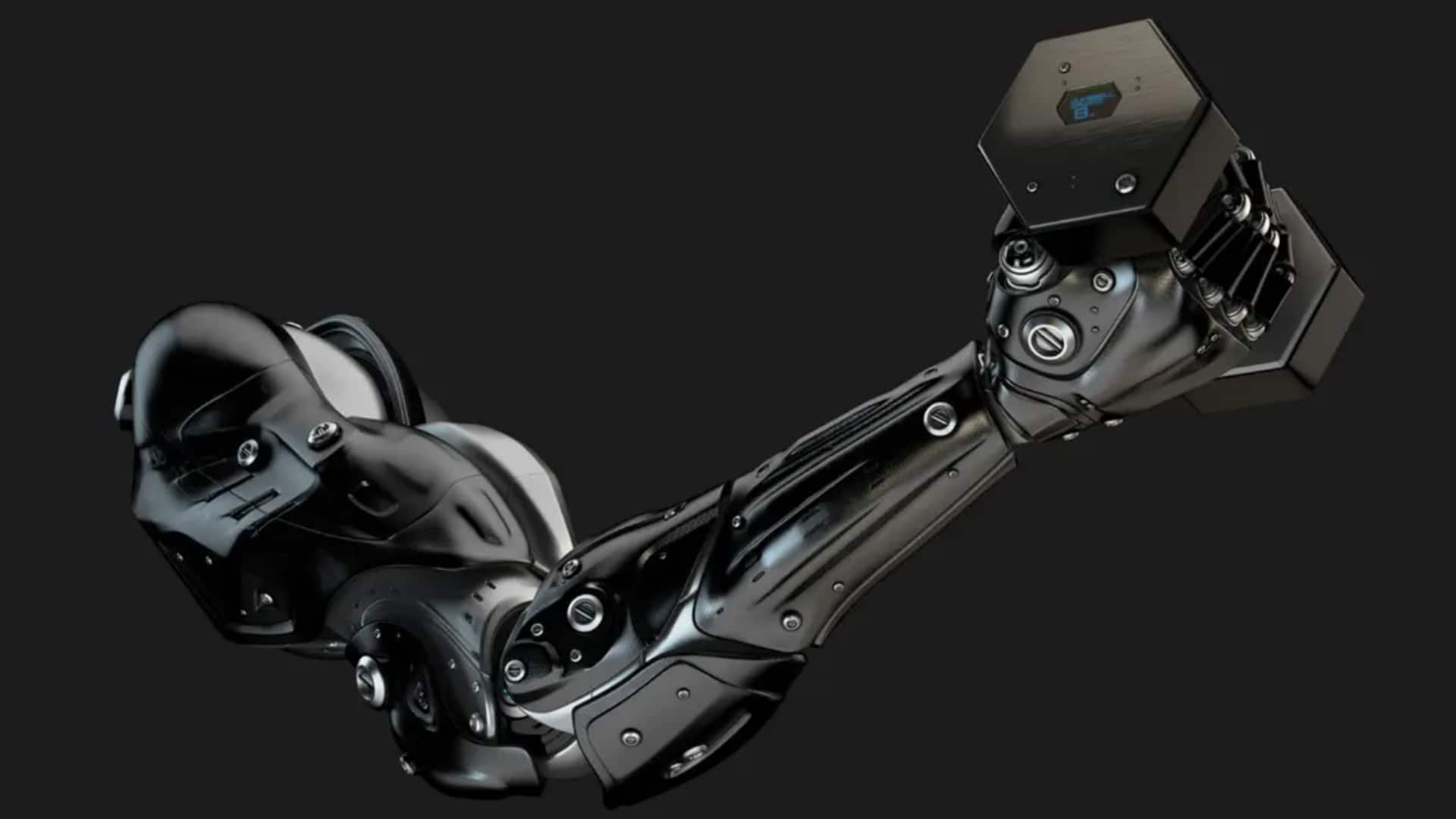

This skin-soft, steel-strong robotic arm can lift 1,000x its weight

What's the story

In a major breakthrough in material science, a team of researchers from the Ulsan National Institute of Science & Technology (UNIST) in South Korea, has developed an innovative magnetic composite artificial muscle. The muscle is as soft as skin but incredibly strong. More interestingly, the new material can adjust its stiffness, going from soft to rigid and vice versa. It has an extraordinary ability to withstand loads comparable to those of automobiles, according to the researchers.

Context

Why does this story matter?

Soft, human-like artificial muscles are crucial for robotics, wearables, and medical devices. Though traditional soft materials enable smooth movement, they lack the strength and precision needed. Current materials are too stiff to lift heavy loads and too flexible to ensure accurate control. The new technological advancement could significantly benefit the soft robotics and wearable technology sectors.

Composition

Development of the artificial muscle

The development of this artificial muscle was led by Professor Hoon Eui Jeong from the Department of Mechanical Engineering at UNIST. To overcome the limitations of existing materials, the team used materials that can switch between hard and soft states. They combined two key components - ferromagnetic particles and shape memory polymers - to create a new type of artificial muscle that is both strong and flexible.

Magnetic reaction

Response to magnetic fields

The researchers employed a unique "surface treatment" to bond the magnetic particles to the shape memory polymer, improving the overall strength and performance of the artificial muscle. This bond enables the muscle to respond quickly and seamlessly to magnetic fields. When a magnetic field is applied, the magnetic particles react, resulting in the muscle changing shape for precise and controlled movements.

Performance

Adaptability and efficiency

The artificial muscles are extremely versatile, able to alter their stiffness by 2,700 times and softness by an amazing eightfold. They can withstand tensile forces 1,000 times their weight and compressive forces 3,690 times their weight. These muscles are beasts of efficiency, converting a whopping 90.9% of the input energy into useful work.

Vibration control

Artificial muscle's design reduces vibrations

The material uses a novel double-layer design, including a vibration-damping hydrogel layer. This allows for unparalleled control and minimizes vibrations of the artificial muscle even at high speeds. "This research opens avenues for transformative applications across diverse sectors, driven by mechanical properties and performance that transcend the limitations of existing artificial muscles," Jeong said. The study appeared in the journal Nature Communications.