Scientists extract gold from e-waste using whey protein: Here's how

What's the story

Scientists have discovered an innovative, eco-friendly method of extracting gold from electronic waste (e-waste) using whey protein sponges, a dairy byproduct. This groundbreaking process is not only 50 times less expensive than the cost of gold but also significantly reduces the energy demands of recycling plants. The research team was led by scientist Raffaele Mezzenga from the Department of Health Sciences and Technology, ETH Zurich.

Context

Why does this story matter?

E-waste is rapidly becoming one of the world's most lucrative untapped industries. Startups in this field are earning substantial profits by extracting gold, copper, and other elements from e-waste. As this industry expands in the coming decades, recyclers will seek more efficient methods for processing e-waste. Mezzanga's sponge technology offers precisely that solution while being significantly cheaper and environmentally friendly.

Methodology

The process: From dairy byproduct to gold extractor

The whey protein sponges are created by denaturing whey proteins under an acidic bath and high temperatures, transforming the substance into a gel. This gel is then dried to form a sponge made out of whey protein fibrils. Before the sponge can be used for extraction, the e-waste must be prepared by dissolving it in an acid bath to ionize the metals.

Extraction

Role of the protein sponge in gold extraction

The sponge is placed in the metal ion solution, where it attracts ionized metals much like a magnet picks up metal shavings. Mezzenga's team discovered that while most metal ions can adhere to the sponge, gold ions do so with greater efficiency. To extract the gold from the sponge, it is heated until the gold ions turn into flakes which can then be easily removed.

Outcome

High purity gold from e-waste

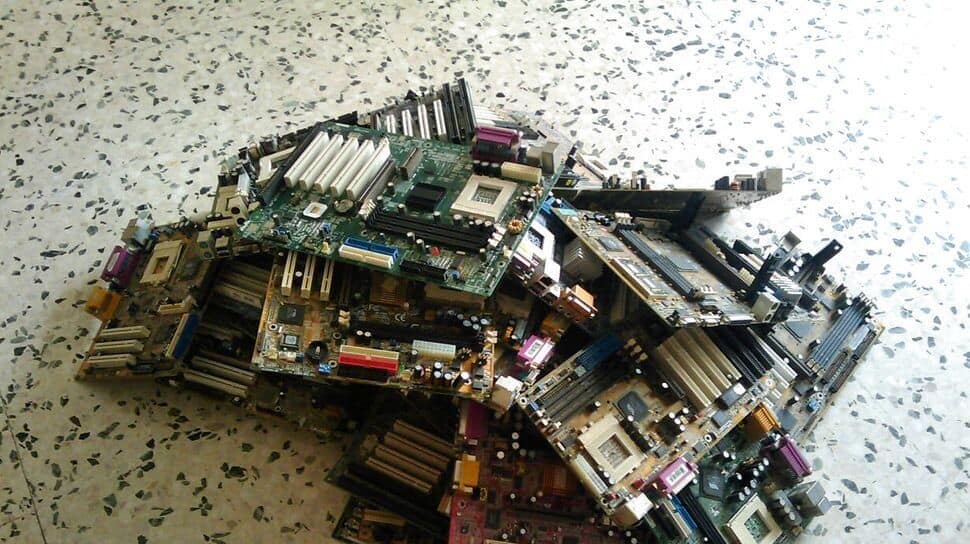

In their tests, Mezzenga and his team were able to melt down all extracted gold into a nugget comprised of 91% gold and 9% copper, equivalent to 22 carats. They found that they could recover around 450mg of gold from 20 motherboards using this method. This innovative technique significantly decreases power demands in recycling plants due to its organic nature.

Future prospects

Commercializing the protein sponge technology

Mezzenga and his colleagues plan to commercialize this technology for use in the e-waste market. They are also exploring the possibility of manufacturing protein sponges from other food industry byproducts or waste. The procurement costs of source materials and energy for extraction are 50 times lower than the value of recoverable gold, making this technique potentially transformative for computer waste processing, particularly those rich in gold.