MIT engineers develop 3D-printed glass bricks for sustainable construction

What's the story

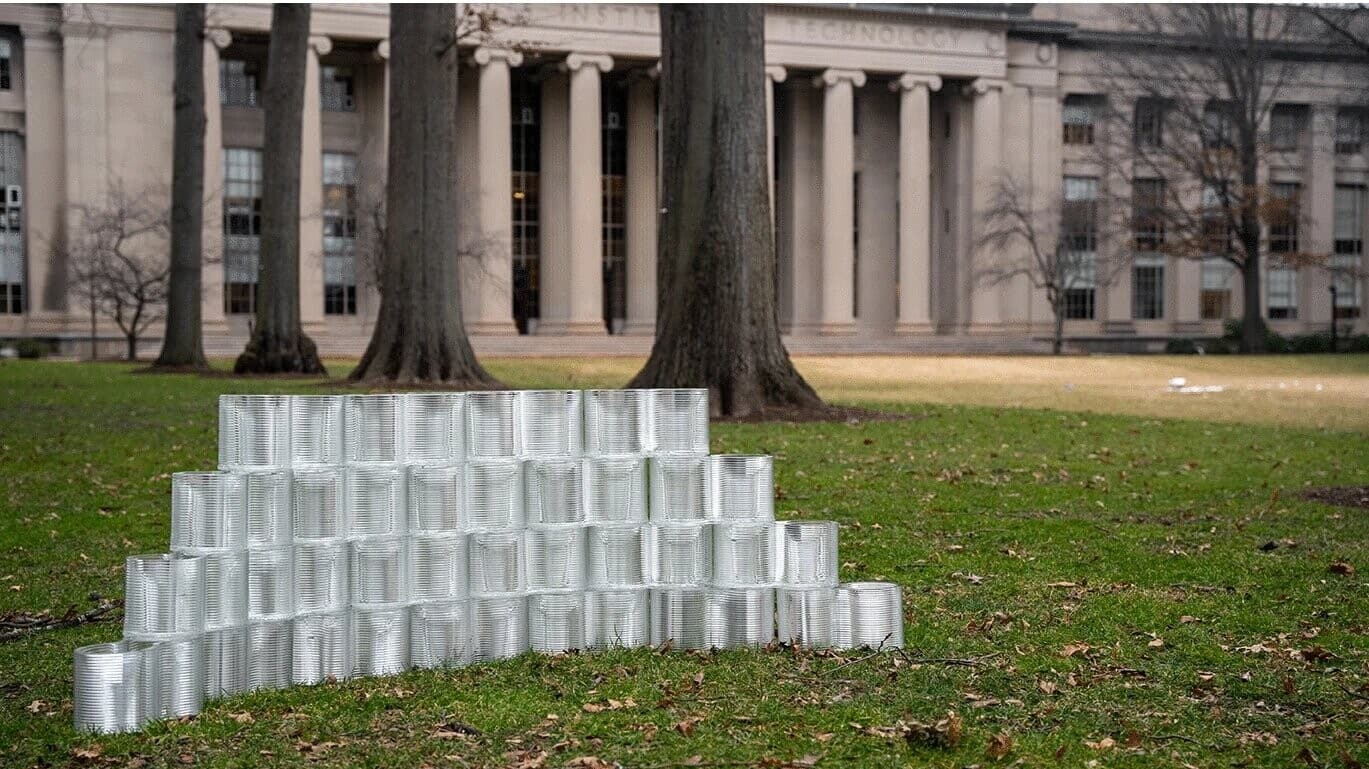

Engineers at the Massachusetts Institute of Technology (MIT) are revolutionizing the construction industry by developing a new type of masonry made from 3D-printed, recycled glass. This innovative approach is inspired by the concept of circular construction, which aims to minimize new material production and reduce greenhouse gas emissions associated with building processes. The team has successfully created robust, multilayered glass bricks using advanced 3D glass printing technology from MIT spinoff Evenline.

Sustainable construction

Glass bricks: A sustainable alternative to traditional masonry

The 3D-printed glass bricks, each shaped like a figure eight, are designed to interlock similar to LEGO bricks. In mechanical tests, these innovative glass bricks demonstrated strength comparable to that of traditional concrete blocks. The team envisions that these recyclable bricks could be repurposed multiple times for building facades and internal walls, significantly reducing the environmental impact of construction projects.

Material potential

A highly recyclable material for construction

Kaitlyn Becker, an assistant professor of mechanical engineering at MIT, highlighted the recyclability of glass as a key factor in its potential as a sustainable building material. "We're taking glass and turning it into masonry that, at the end of a structure's life, can be disassembled and reassembled into a new structure," she said. This innovative approach challenges traditional perceptions about the use of glass in construction and pushes architectural boundaries.

Evolution

The journey from glassblowing to 3D-printed masonry

The idea for this innovative masonry design was conceived in MIT's Glass Lab, where Becker and Michael Stern, a former MIT graduate student and researcher, first explored the art of glassblowing. Stern later designed a 3D printer capable of printing molten recycled glass while studying mechanical engineering. Meanwhile, Becker began investigating the intersection of manufacturing and design with a focus on developing new processes that enable innovative designs.

Production process

The process of creating 3D-printed glass bricks

To create the 3D-printed glass bricks, the team used Evenline's Glass 3D Printer 3 (G3DP3), which pairs with a furnace to melt crushed glass bottles into a printable form. The printer then deposits this molten material in layered patterns to form the bricks. Each brick was printed with two round pegs, similar to LEGO studs, allowing them to interlock and assemble into larger structures. This innovative design enables easy assembly and disassembly of structures, further promoting sustainability in construction.