Chinese scientists innovate low-cost optical chip production to thwart US

What's the story

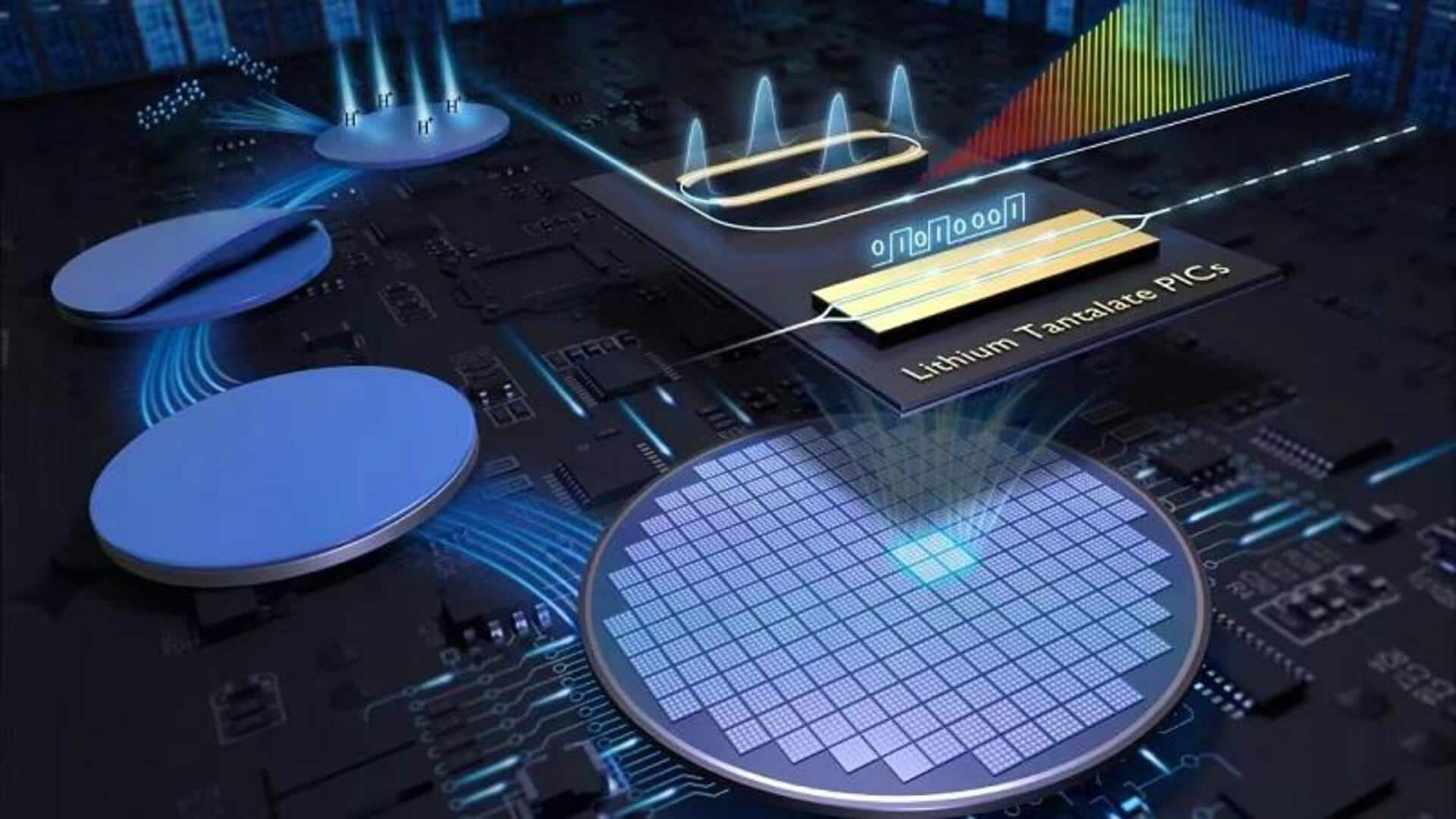

Chinese researchers have pioneered a cost-effective method to mass-produce photonic integrated circuits (PICs), potentially mitigating the effects of US sanctions. These optical chips, which utilize photons for processing and transmitting data, are integral to supercomputers and data centers. PICs are known for enhancing transmission speeds and minimizing energy usage, in fiber optic communications or photonic computing.

Innovation

New semiconductor material reduces costs

The production of PICs often involves materials like lithium niobate, recognized for its superior ability to convert electronic data into photonic information. However, as per the research team, the high cost per wafer and limited wafer size, have been obstacles to the industrial application of this technology. In a recent publication in Nature, the scientists proposed an alternative semiconductor material: lithium tantalate (LiTaO3), which promises better performance and affordability.

Material advantage

Lithium tantalate: A superior, cost-effective alternative

Lithium tantalate, already commercially used for 5G radiofrequency filters in smartphones, promises scalable manufacturing at low costs. According to the research team's paper, it possesses equal or superior properties compared to lithium niobate. The fabrication process of PICs comprises patterning the wafers using lithographic techniques. This is followed by etching as well as material deposition. The team developed compatible processing technologies for lithium tantalate wafers, using a manufacturing process requiring a deep ultraviolet stepper.

Production milestone

A step toward self-sufficiency

This new technique could help China lessen the impact of US-imposed export controls and sanctions that limit China's access to advanced chips, as well as manufacturing equipment. Novel Si Integration Technology, a Shanghai-based start-up, has already developed the capacity for mass-production of eight-inch wafers with this new material. The company has also developed commercially viable micro-manufacturing processes, providing a material basis for local optical and radiofrequency chips.