Scientists create artificial veins that could transform heart bypass surgery

What's the story

Researchers at the University of Edinburgh have achieved a significant breakthrough in heart surgery, by developing artificial blood vessels using 3D printing technology. These innovative gel-like tubes closely mimic human veins and could potentially revolutionize heart bypass surgery, enhancing patient outcomes globally. The development also promises to reduce healthcare costs and increase accessibility to life-saving procedures.

Customization potential

Personalized medicine in cardiovascular care

The artificial blood vessels offer a path toward personalized medicine in cardiovascular care, allowing for the creation of custom-made artificial blood vessels to meet individual patient needs. According to a press release, "The 3D graft can be made in thicknesses from 1 to 40mm in diameter, for a range of applications, and its flexibility means that it could easily be integrated into the human body."

Biomechanical properties

Research addresses long-standing vascular tissue challenge

Dr. Norbert Radacsi, the principal investigator of the study, stated that their research has addressed a long-standing challenge in vascular tissue engineering: producing a conduit with biomechanical properties similar to human veins. "The vision of improved treatment options for patients with cardiovascular disease could become a reality," said Radacsi, highlighting the potential impact of this breakthrough on future medical treatments.

Bypass surgery

3D-printed blood vessels: A solution to surgical limitations

Heart bypass surgery traditionally involves restoring blood flow to the heart muscle when coronary arteries become blocked or narrowed. This procedure typically requires harvesting veins from the patient's own body, which can lead to complications such as scarring, pain, and an increased risk of infection. The newly-developed 3D-printed blood vessels offer a promising solution by offering a readily available, and customizable alternative to harvested veins.

Production technique

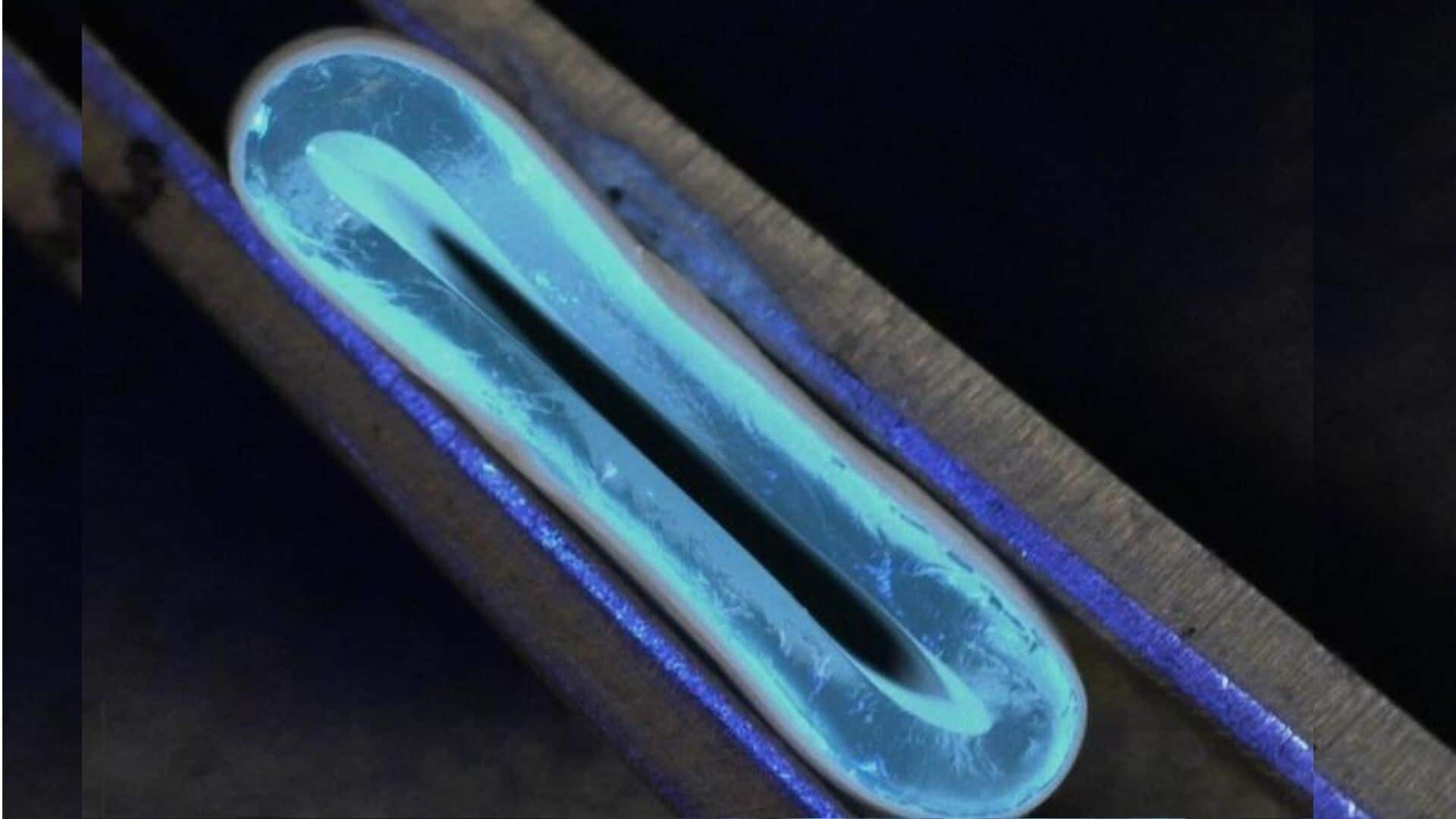

Two-stage process achieves artificial blood vessel milestone

The research team achieved this milestone through a two-stage process. Initially, they used a 3D printer equipped with a rotating spindle to produce tubular grafts from a water-based gel. Subsequently, these grafts were reinforced through electrospinning, which applies an ultra-thin coating of biodegradable polyester nanofibers using high voltage. This technique resulted in artificial vessels exhibiting strength comparable to natural blood vessels and flexibility for seamless integration into the human body.

Future applications

Hybrid technique opens new possibilities in tissue engineering

Dr. Faraz Fazal, lead author of the study, expressed that their hybrid technique opens doors to new and exciting possibilities for the fabrication of tubular constructs in tissue engineering. The research could also benefit other fields of regenerative medicine, thanks to its ability to create complex, biomimetic structures through 3D printing and electrospinning. The team now plans to test these artificial blood vessels in animal models as the next phase of their research.