Enhancing natural wood sealer with tung oil

What's the story

Tung oil, extracted from the seeds of the tung tree, has been utilized for hundreds of years to preserve and beautify wood surfaces.

It seeps deep into the wood, forming a water-resistant finish that simultaneously permits the wood to breathe.

This guide delves into the art of using tung oil as a natural wood sealer, providing tips on preparation, application, maintenance, and safety.

Preparation

Preparing wood for tung oil application

Before applying tung oil, you need to ensure the wood surface is adequately prepared.

Start by sanding the wood with fine-grit sandpaper until it is smooth.

Then, wipe away any dust with a tack cloth or a damp rag, and let it dry thoroughly.

Proper preparation ensures the tung oil bonds well with the wood, resulting in a smooth and even finish.

Application

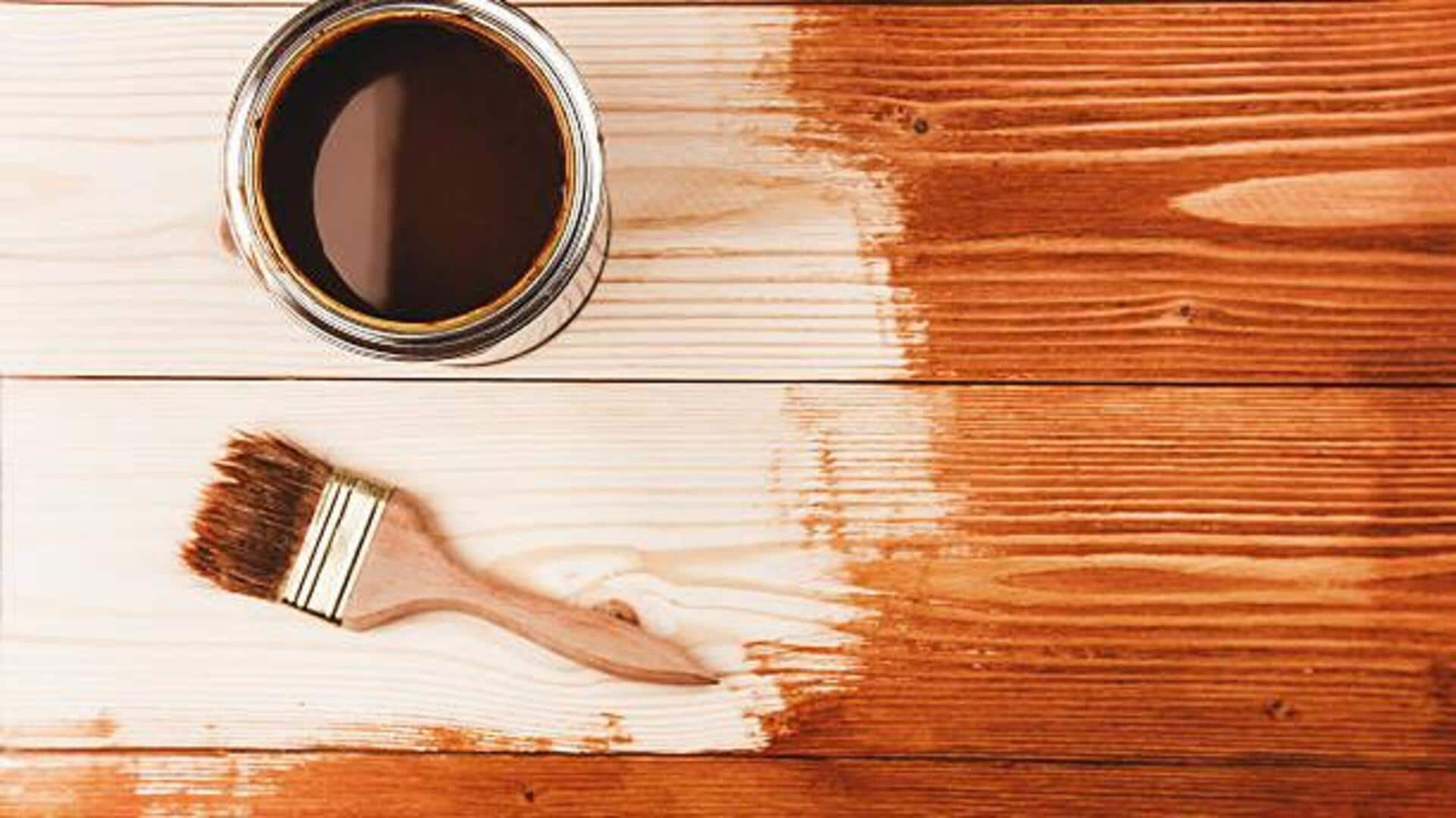

Applying tung oil correctly

To apply tung oil properly, use a clean brush or rag to apply thin layers.

Let each layer penetrate for a minimum of 40 minutes, then remove any excess oil with a clean cloth.

Achieving the perfect finish typically requires three to four coats.

Keep in mind that drying times are dependent on temperature and humidity conditions, so patience is essential.

Maintenance

Maintaining tung oil finish on wood

Keeping a tung oil finish looking its best is easy, but it does need some regular love.

Every few months, give the surface a light scuffing with ultra-fine sandpaper and apply another coat of tung oil.

This will not only refresh the finish but also strengthen its protection against moisture and wear.

Safety

Safety tips when working with tung oil

Although tung oil is natural and safer compared to synthetic finishes, you should always work in a well-ventilated area due to its strong odor.

Wear gloves to prevent skin irritation and avoid contact with eyes.

Dispose of or store the used application rags in a sealed metal container as they pose a risk of spontaneous combustion if left improperly stored.